High-temperature flex hoses are vital within a wide range of industries to allow for the transfer of liquids or gas at high temperature whilst keeping the surrounding equipment, applications, and people safe from harm. This type of hosing is designed to withstand high temperatures and remain safe and effective when faced with extreme temperatures, high humidity levels, and the presence of chemicals, steam, and other potentially damaging fluids and gasses.

Different industries where high-temperature flex hose is used

To understand how important the role of a high-temp flex hose is, you must first see the types of industries and appliances that it is used within.

Manufacturing

Manufacturing environments can be harsh when discussing the industrial scale, and high-temp flex hose is used to protect liquids and gasses that are passing through applications without contaminating or damaging the materials that are passing through the production process.

Aerospace

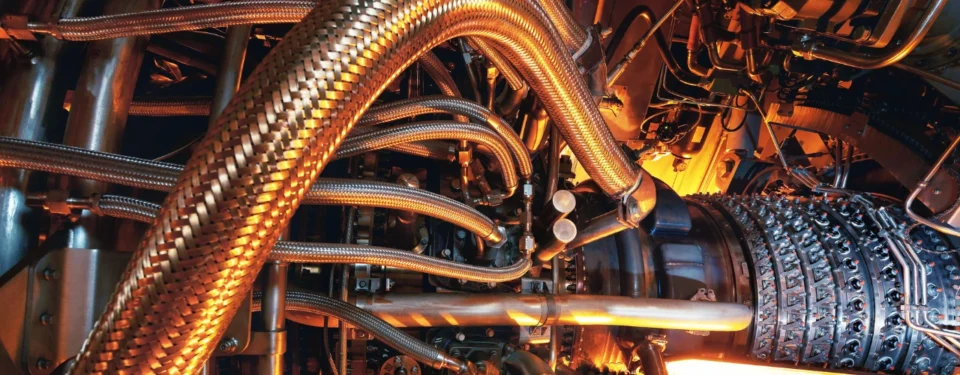

The manufacture of aircraft engines often takes place under extremely high operating temperatures. Materials are used in the process that can withstand extreme temperatures, and therefore silicone heater hoses are used inside these engines.

Mining

Flex hoses that can withstand high temperatures are found within applications in mining operations. This is dangerous work, with high temperatures and potentially dangerous fluids and chemicals present, leading to the need for the highest protective hose sleeving possible.

Automotive

Whether the manufacture of cars for the general public or the design and build of race cars for motorsport, high-temp flex hoses are used to transfer fluids from one part of a car to another. They are designed to withstand high heat and be resistant to harsh weather conditions.

Marine

Engine rooms of ships and other applications within the marine sector are harsh environments. Protecting industrial applications and the workers in marine locations is vital. A high-temperature flex hose provides this level of protection.

Silicone fire hose sleeves provide the perfect protection for a variety of industrial applications; a safety net against overheating equipment, chemical and fluid leaks, and a better protection against injuries such as burns. Protecting both the worker and the application is important to any business where a high-temp flex hose is installed. Ensuring that operations run smoothly, that downtime is minimised, and that everyone is safe during the operation is paramount, and with the highest quality of silicone flex hose in place, this is possible.

Flexible high temperature hoses provide safety in a variety of industries and applications that are dangerous due to the presence of extremely high temperatures, chemicals, and gasses. Hose sleeve protection and high temperature houses are used in the automotive industry, in industrial settings, in engine rooms within the marine sector, mining, and other applications. Choosing the right silicone hose manufacturer for your business needs will depend on a range of circumstances, the industry and the applications that you require assistance with. In locations where there is extreme heat, it is important to have as many secure safety features as possible. This ensures that safety is paramount for all people working and passing by in the vicinity.