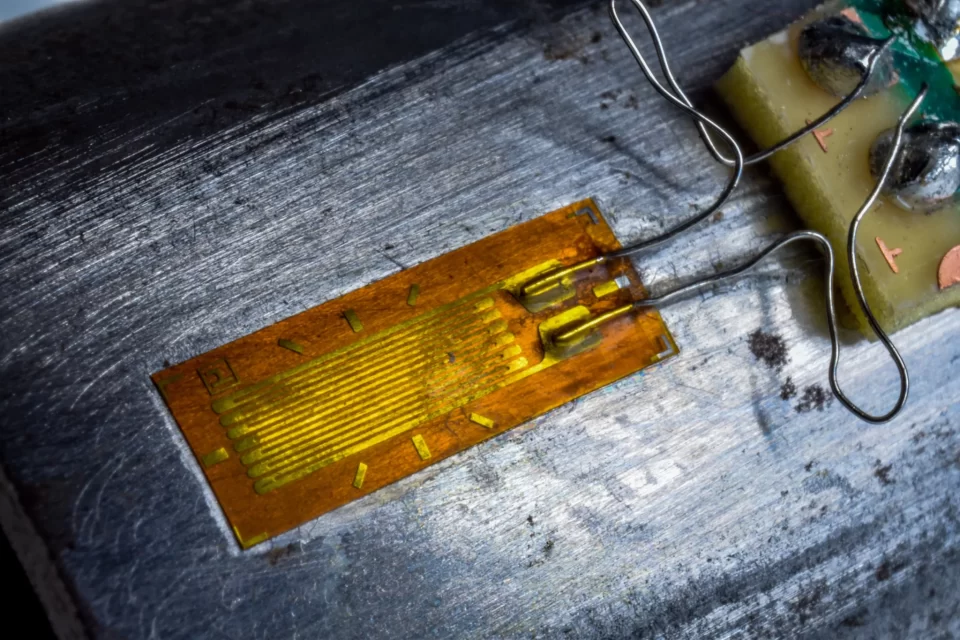

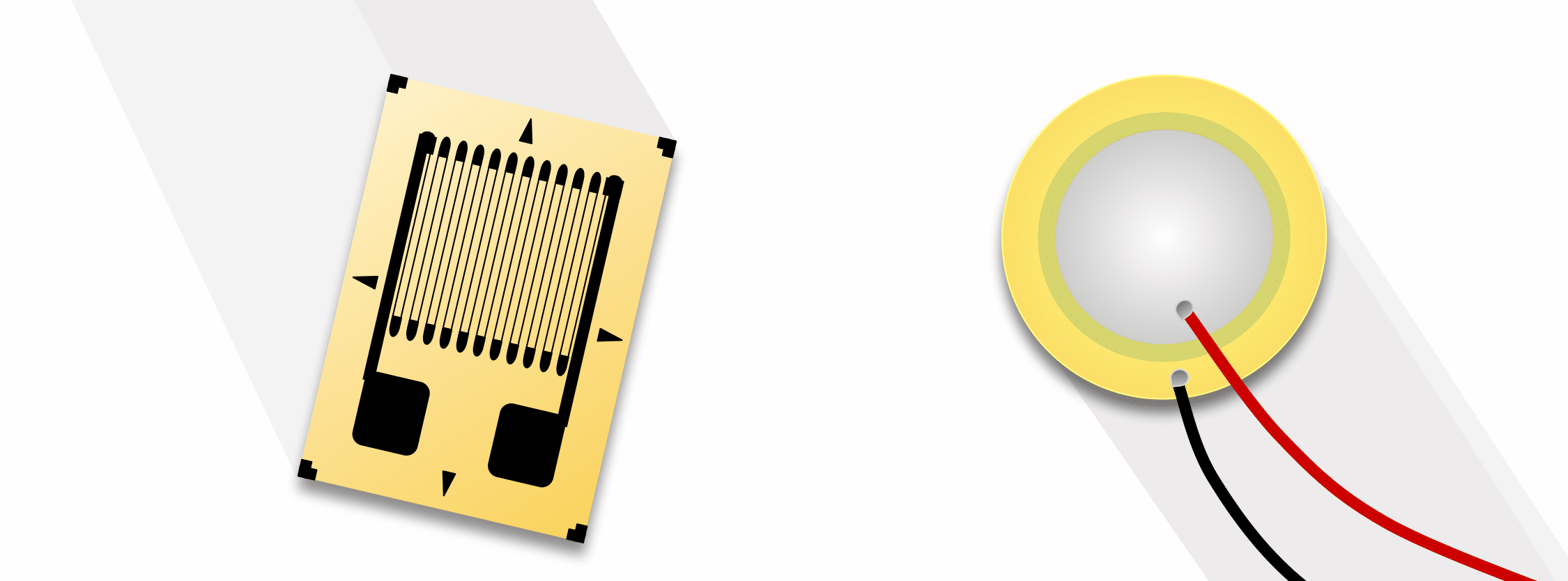

Strain gauges play a crucial role in testing the strength and durability of various materials and objects. These small devices measure the strain or deformation that occurs when a material is subjected to stress. By accurately capturing this data, strain gauges provide valuable insights into the performance and resilience of materials under different conditions. Understanding how materials respond to forces is essential for designing safe and reliable products.

Find below five benefits of using strain gauges when testing the strength and durability of materials and objects.

High precision and accuracy

Strain gauges measure deformation with extreme precision and accuracy. Their ability to identify even minute variations in length is critical for assessing the performance of materials. Because of this degree of precision, engineers and researchers know they can trust the information to make wise choices about the composition and characteristics of materials.

Real-time monitoring

The capacity of strain gauges to offer real-time stress and strain monitoring is one of its main features. This capability makes it possible to continuously see how materials behave under different loads. Real-time data facilitates prompt interventions and revisions by assisting in the identification of any emerging problems or flaws in the content.

Versatility

Strain gauges are versatile and can be used on a wide range of materials and structures, from metals and composites to bridges and aircraft. This adaptability makes them invaluable in various fields, including civil engineering, aerospace, automotive, and manufacturing. Their ability to measure strain in different environments and applications broadens their utility.

Cost-effective testing

Using strain gauges is a cost-effective method for testing materials. The gauges themselves are relatively inexpensive, and their application does not require extensive or costly equipment. This affordability makes strain gauges accessible for both large-scale industrial applications and smaller research projects.

Enhanced safety and reliability

By accurately measuring strain and stress, strain gauges help ensure the safety and reliability of structures and components. The data obtained from these measurements can predict potential failures and guide improvements in material design and construction. This proactive approach enhances the overall safety and durability of products and structures.

Final thoughts

Strain gauges are essential tools in the field of material testing. Whether in engineering, manufacturing, or research, strain gauges provide critical insights that drive innovation and improve the quality and safety of products and structures. By using strain gauges, professionals can ensure that materials perform as expected under different conditions, leading to safer and more reliable outcomes.